The device slicing device has a great structure, which allows sturdy machining with a massive amount of reducing, for that reason enhancing the processing traditional overall performance of the tool lowering machine. the kind of rotation pace and feed of the tool cutting tool spindle is more than that of normal device tool, so the maximum favorable lowering amount can be determined on for each manner of the device system tool.

Contact Now

When many customers come to our factory to inspect the cutting machine equipment of the machining center, they often cannot distinguish the multi-process cutting machine and the cutting machine processing center, and do not know the difference between them, so they often do not know the choice when purchasing Which one, let's explain the difference between them.The first is the multi-process cutting machine. The multi-process cutting machine mainly includes two-process cutting machine, three-process cutting machine and four-process cutting machine.

Contact Now

The device reducing tool has a awesome shape, which lets in sturdy machining with a huge quantity of reducing, as a end result enhancing the processing regular average overall performance of the tool decreasing gadget. the style of rotation pace and feed of the device reducing device spindle is greater than that of normal device machine, so the maximum favorable cutting amount can be decided on for each technique of the tool device device.

Contact Now

The disadvantage of the multi-process cutting machine is that what should I do if the knife is used more? It is too troublesome to manually replace the tool if the machine head is not enough, so the cutting machine machining center came into being. The cutting machine machining center was born to solve this problem. When the program needs to replace the required tool, the program will automatically control the spindle motor to the position of the tool magazine and replace the required tool without manual intervention.

Contact Now

Multi-process cutting machine mainly includes two-process cutting machine, three-process cutting machine and four-process cutting machine. According to the number of processes, different cutting machines are equipped with different spindle motors, and one motor is equipped with different tools.

Contact Now

Automatic tool setting, setting automatic tool setting instrument, automatic tool setting, good accuracy and high efficiency.The Four Process Cutting Machine is suitable for panel furniture, solid wood furniture, solid wood composite doors, etc.

Contact Now

The saw blade machine can cut the material thicker and faster than the ordinary cutter machine, and the multi-saw blade machine can meet the cutting in various directions.Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising CompanyFeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punc

Contact Now

Applicable Relevant to all sorts of stone, metal, jade, crystal, timber, synthetic materials, artificial substances, and so forth.;Utilized in inscriptions, garden engineering, large-scale sculptures, handicraft carvings, domestic ornament, video walls and other industries;Function: embossing, lettering, hollowing out, cutting, seamless splicing, surface remedy, table pinnacle milling, etc. FeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punching.

Contact Now

The tool slicing system has a terrific structure, which allows sturdy machining with a massive quantity of slicing, as a result improving the processing performance of the tool slicing gadget. the form of rotation pace and feed of the device cutting device spindle is bigger than that of everyday tool tools, so the most favorable decreasing quantity may be decided on for every process of the device machine tool.

Contact Now

The tool cutting machine is processed according to the instructions given in digital form. Generally, the working process does not require manual intervention, which eliminates the error caused by the operator. When designing and manufacturing the tool machine tool, many measures have been taken to achieve high precision and rigidity of the mechanical part of the tool cutting machine. In addition, the drive system and structure of the knife cutting machine have high rigidity and thermal stability.

Contact Now

The cutter slicing gadget can realize the movement of just about any trajectory and process the workpiece of any shape, and is suitable for the processing of complex unique-fashioned parts.FeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punching. It is the preferred equipment for the production of customized furniture in the whole house. The main functions are as follows:1. Accurate positioning.

Contact Now

In the case of single-piece, small batch production, machining with a cutter cutting machine can reduce adjustment, machining and inspection time and save direct production costs. The machining accuracy of the tool cutting machine is stable, which reduces the scrap rate and further reduces the production cost. Therefore, the use of knife cutting machine can obtain good economic benefits.FeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punching.

Contact Now

The tool cutting machine has a good structure, which allows robust machining with a huge quantity of slicing, thus improving the processing performance of the tool slicing system. the variety of rotation pace and feed of the tool cutting machine spindle is larger than that of everyday device gear, so the most favorable reducing quantity may be selected for every process of the device gadget tool.

Contact Now

The tool cutting machine is processed according to the instructions given in digital form. Generally, the working process does not require manual intervention, which eliminates the error caused by the operator. When designing and manufacturing the tool machine tool, many measures have been taken to achieve high precision and rigidity of the mechanical part of the tool cutting machine. In addition, the drive system and structure of the knife cutting machine have high rigidity and thermal stability.

Contact Now

The tool cutting machine has a good structure, which allows strong machining with a large amount of cutting, thus improving the processing efficiency of the tool cutting machine. The range of rotation speed and feed of the tool cutting machine spindle is larger than that of ordinary machine tools, so the most favorable cutting amount can be selected for each process of the tool machine tool.

Contact Now

The tool cutting machine is processed according to the instructions given in digital form. Generally, the working process does not require manual intervention, which eliminates the error caused by the operator. When designing and manufacturing the tool machine tool, many measures have been taken to achieve high precision and rigidity of the mechanical part of the tool cutting machine. In addition, the drive system and structure of the knife cutting machine have high rigidity and thermal stability.

Contact Now

4-axis spindle swing engraving machine, the main shaft can swing 180 degrees, and 8 linear tool changers can be selected to meet the needs of different processing processes. gift industry. The 4-axis spindle swing engraving machine can swing and engrave along the X-axis direction or along the Y-axis direction, and process various special-shaped molds, wood mold molds, etc. The machine is highly flexible and can replace a large part of the work of a five-axis engraving machine. If the customer requires the spindle to rotate 360 degrees, it is the five-axis mold machining center.

Contact Now

Strong adaptability is the outstanding advantage of the knife cutting machine. Adaptability, the so-called flexibility, refers to the adaptability of the tool machine tool to changes in production objects. When changing the machining part on the tool machine, it is only necessary to reprogram the program and input the new program to realize the machining of the new part; there is no need to change the hardware of the mechanical part and the control part, and the production process is completed automatically.

Contact Now

Strong adaptability is the outstanding advantage of the knife cutting machine. Adaptability, the so-called flexibility, refers to the adaptability of the tool machine tool to changes in production objects. When changing the machining part on the tool machine, it is only necessary to reprogram the program and input the new program to realize the machining of the new part; there is no need to change the hardware of the mechanical part and the control part, and the production process is completed automatically.

Contact Now

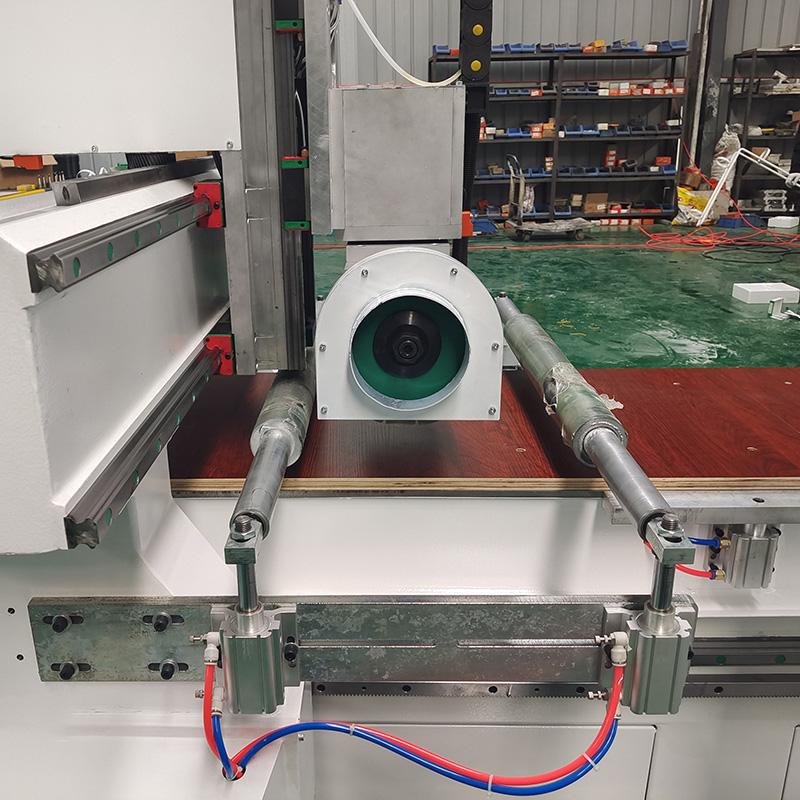

FeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punching. It is the preferred equipment for the production of customized furniture in the whole house. The main functions are as follows:1. Accurate positioning. The CNC cutting machine has 6 positioning cylinders, which is fast in positioning and more convenient in changing plates.2. Stable model. All three axes use original linear square rails, which have good stability, long service life and high precision.3.

Contact Now

The cutting machine is a commonly used CNC woodworking machine in the production of solid wood furniture.

Contact Now

The cutter cutting machine can realize the movement of almost any trajectory and process the workpiece of any shape, and is suitable for the processing of complex special-shaped parts.FeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punching. It is the preferred equipment for the production of customized furniture in the whole house. The main functions are as follows:1. Accurate positioning.

Contact Now

In the machining process, the common methods of sheet cutting include manual cutting, semi-automatic cutting machine cutting and CNC cutting machine cutting. Manual cutting is flexible and convenient, but the quality of manual cutting is poor, the size error is large, the material waste is large, the subsequent processing workload is large, and the labor conditions are harsh and the production efficiency is low. Among the semi-automatic cutting machines, the profiling cutting machine has better quality of cutting workpieces.

Contact Now

Applicable Applicable to all kinds of stone, metallic, jade, crystal, wood, artificial substances, synthetic materials, and so on.;Utilized in inscriptions, lawn engineering, huge-scale sculptures, handicraft carvings, domestic ornament, video walls and different industries;Characteristic: embossing, lettering, hollowing out, cutting, seamless splicing, floor treatment, table top milling, and so on. FeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punching.

Contact Now