The tool reducing gadget is processed according to the commands given in virtual form. typically, the running system does no longer require guide intervention, which gets rid of the mistake due to the operator. when designing and manufacturing the tool system tool, many measures were taken to attain excessive precision and pressure of the mechanical a part of the device reducing device. in addition, the drive machine and structure of the knife slicing system have excessive tension and thermal balance.

Contact Now

Strong adaptability is the tremendous benefit of the knife slicing system. adaptability, the so-known as flexibility, refers to the adaptability of the tool machine tool to adjustments in manufacturing objects. whilst converting the machining part on the device device, it is best essential to reprogram this system and enter the brand new application to recognize the machining of the new element; there may be no want to alternate the hardware of the mechanical element and the manipulate element, and the manufacturing system is completed robotically.

Contact Now

The device reducing device is processed in step with the instructions given in digital form. commonly, the running manner does now not require manual intervention, which gets rid of the error due to the operator. at the same time as designing and production the tool tool tool, many measures were taken to build up immoderate precision and strain of the mechanical part of the tool lowering tool. in addition, the stress device and shape of the knife slicing tool have immoderate strain and thermal balance.

Contact Now

The tool slicing device is processed in keeping with the instructions given in digital form. commonly, the operating way does now not require guide intervention, which gets rid of the error due to the operator. whilst designing and manufacturing the tool tool device, many measures had been taken to gather immoderate precision and strain of the mechanical part of the device reducing machine. further, the pressure device and structure of the knife slicing device have excessive pressure and thermal stability.

Contact Now

The tool slicing system has a terrific structure, which allows sturdy machining with a massive quantity of slicing, as a result improving the processing performance of the tool slicing gadget. the form of rotation pace and feed of the device cutting device spindle is bigger than that of everyday tool tools, so the most favorable decreasing quantity may be decided on for every process of the device machine tool.

Contact Now

The tool decreasing device is processed in step with the instructions given in digital form. commonly, the walking way does now not require guide intervention, which gets rid of the mistake because of the operator. on the identical time as designing and manufacturing the device tool tool, many measures were taken to build up excessive precision and pressure of the mechanical part of the tool lowering tool. in addition, the pressure tool and form of the knife cutting tool have immoderate stress and thermal stability.

Contact Now

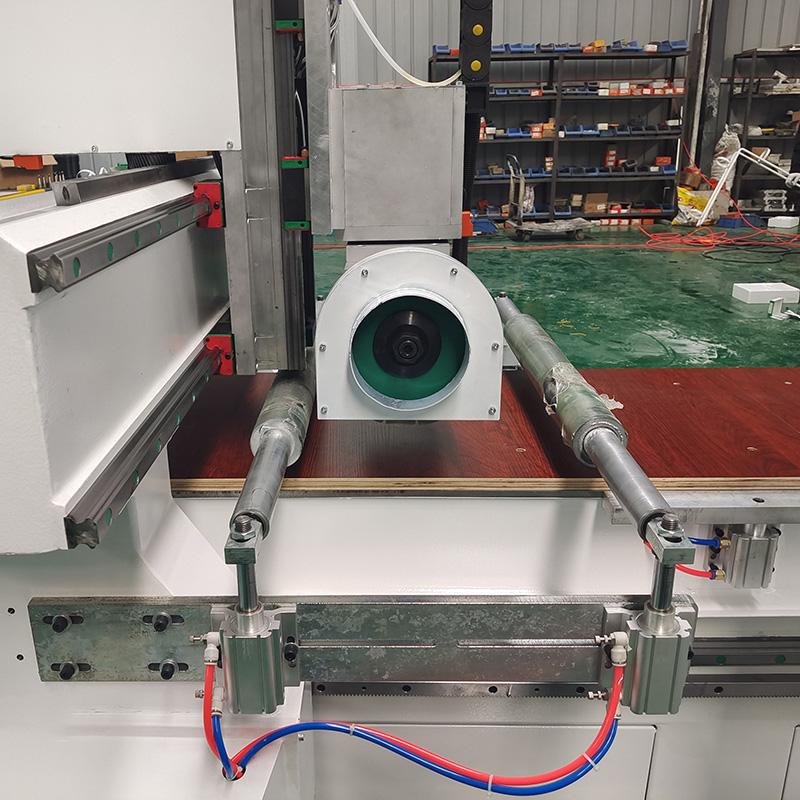

Cutting cloth, leather for clothes, bag and shoesCutting different composite materials for toy Cutting KT board for advertisingCutting PVC pad, slipcover, non-slip mat for home furnishingCutting car seat cover, wire ring pad for auto industryCutting corrugated paper etc for package industry Core advantages:● Structure: The fuselage is welded by high-strength thick-walled steel pipes, which are annealed and sandblasted to ensure stable structure and guaranteed accuracy.● Accessories: Servo motor drive, Taiwan imported 25 guide rail screw // Chint electrical components, etc., stable pe

Contact Now

The tool cutting machine is processed according to the instructions given in digital form. Generally, the working process does not require manual intervention, which eliminates the error caused by the operator. When designing and manufacturing the tool machine tool, many measures have been taken to achieve high precision and rigidity of the mechanical part of the tool cutting machine. In addition, the drive system and structure of the knife cutting machine have high rigidity and thermal stability.

Contact Now

The tool cutting machine has a good structure, which allows robust machining with a huge quantity of slicing, thus improving the processing performance of the tool slicing system. the variety of rotation pace and feed of the tool cutting machine spindle is larger than that of everyday device gear, so the most favorable reducing quantity may be selected for every process of the device gadget tool.

Contact Now

The tool decreasing device is processed steady with the instructions given in virtual shape. usually, the taking walks way does no longer require manual intervention, which receives rid of the mistake due to the operator. on the equal time as designing and manufacturing the device tool device, many measures have been taken to accumulate immoderate precision and pressure of the mechanical a part of the device lowering device. in addition, the strain tool and form of the knife decreasing device have excessive stress and thermal balance.

Contact Now

The cutter slicing gadget can realize the movement of just about any trajectory and process the workpiece of any shape, and is suitable for the processing of complex unique-fashioned parts.FeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punching. It is the preferred equipment for the production of customized furniture in the whole house. The main functions are as follows:1. Accurate positioning.

Contact Now

The device cutting gadget has a high-quality form, which lets in strong machining with a massive amount of reducing, as a end result enhancing the processing typical overall performance of the device lowering gadget. the fashion of rotation pace and feed of the device lowering tool spindle is greater than that of everyday system equipment, so the maximum favorable cutting amount can be determined on for every approach of the tool gadget device.

Contact Now

The device cutting machine has a incredible form, which permits robust machining with a large amount of slicing, as a result improving the processing performance of the device cutting gadget. the variety of rotation tempo and feed of the device cutting system spindle is greater than that of regular gadget gear, so the maximum favorable cutting quantity may be selected for every approach of the tool gadget device.

Contact Now

The device cutting gadget is processed in line with the instructions given in virtual form. typically, the operating manner does not require guide intervention, which eliminates the mistake caused by the operator. when designing and production the device device tool, many measures were taken to acquire excessive precision and pressure of the mechanical part of the device cutting machine. similarly, the force machine and structure of the knife cutting gadget have excessive stress and thermal stability.

Contact Now

The tool cutting machine is processed according to the instructions given in digital form. Generally, the working process does not require manual intervention, which eliminates the error caused by the operator. When designing and manufacturing the tool machine tool, many measures have been taken to achieve high precision and rigidity of the mechanical part of the tool cutting machine. In addition, the drive system and structure of the knife cutting machine have high rigidity and thermal stability.

Contact Now

FeaturesThe disc tool changer + sub-mom saw processing center creates an smart production technique for panel fixtures cutting and punching. it's far the desired device for the production of customized furnishings in the entire residence. The primary capabilities are as follows:1. Accurate positioning. The CNC cutting machine has 6 positioning cylinders, which is fast in positioning and more convenient in changing plates.2. Stable model. All three axes use original linear square rails, which have good stability, long service life and high precision.3.

Contact Now

The sub-mom noticed system can substantially lessen operating time, improve work efficiency and shop labor. it is broadly used in reducing and engraving of diverse sorts of plates, whole-residence customization, steel and non-steel materials, and so on., with high precision, high efficiency and fast velocity.FeaturesThe disc tool changer + sub-mother saw processing center creates an intelligent production process for panel furniture cutting and punching. It is the preferred equipment for the production of customized furniture in the whole house. The main functions are as follows:1.

Contact Now

High precision grinding willing rack is followed, that is matched with imported linear square rail to enhance the accuracy and ensure that it's going to not be affected throughout lengthy-time operation.

Contact Now

3KW industrial grade motor with strong power. The whole machine is made of reinforced steel structure, with better rigidity and durability.450mm saw blade can be installed to reach 600mm cutting length, which can meet the cutting of large size fireproof phenolic boardHigh-precision guide rails ensure the stability and accuracy of cutting work Reliable special fixture, water supply device, can quickly perform wet cutting. No dust, low noise, high precision, especially suitable for various prospecting and other mineral engineering quality inspection core samples.

Contact Now

The tool cutting machine has a good structure, which allows strong machining with a large amount of cutting, thus improving the processing efficiency of the tool cutting machine. The range of rotation speed and feed of the tool cutting machine spindle is larger than that of ordinary machine tools, so the most favorable cutting amount can be selected for each process of the tool machine tool.

Contact Now

When many customers come to our factory to inspect the cutting machine equipment of the machining center, they often cannot distinguish the multi-process cutting machine and the cutting machine processing center, and do not know the difference between them, so they often do not know the choice when purchasing Which one, let's explain the difference between them.The first is the multi-process cutting machine. The multi-process cutting machine mainly includes two-process cutting machine, three-process cutting machine and four-process cutting machine.

Contact Now

The tool is ready with a preservation machine with excessive pace and excessive precision. one device can deal with a selection of merchandise.

Contact Now

Strong adaptability is the outstanding advantage of the knife cutting machine. Adaptability, the so-called flexibility, refers to the adaptability of the tool machine tool to changes in production objects. When changing the machining part on the tool machine, it is only necessary to reprogram the program and input the new program to realize the machining of the new part; there is no need to change the hardware of the mechanical part and the control part, and the production process is completed automatically.

Contact Now

Solid shape, simple operation, various functions and durability one machine molding, gifted in the entirety.

Contact Now