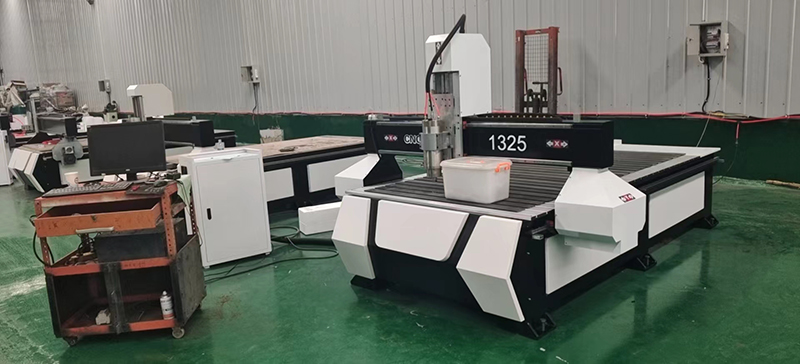

Wood Cnc Router Machine

1. High production efficiency

2. High precision and high reliability;

3. Can process complex workpieces;

4. Strong adaptability;

5. Good economic benefits;

The tool cutting machine has a good structure, which allows strong machining with a large amount of cutting, thus improving the processing efficiency of the tool cutting machine. The range of rotation speed and feed of the tool cutting machine spindle is larger than that of ordinary machine tools, so the most favorable cutting amount can be selected for each process of the tool machine tool. The moving parts of the tool machine tool have fast idle travel speed, short workpiece clamping time, automatic tool replacement, and greatly reduced auxiliary time compared with ordinary machine tools.

Scope of application:

Used for advertising industry, woodworking industry and all kinds of plate CNC engraving, cutting, drilling, trimming and special-shaped carving and other functions.

Core advantages:

● Structure: The fuselage is welded by high-strength thick-walled steel pipes, which are annealed and sandblasted to ensure stable structure and guaranteed accuracy.

● Accessories: Servo motor drive, Taiwan imported 25 guide rail screw // Chint electrical components, etc., stable performance and durable.

● Accuracy: Excellent accessories and precise detection devices enable the product to obtain perfect positioning and running accuracy.

● High speed: high-power servo motor and precision reducer are directly connected to design, high torque, high kinetic energy, smooth operation and high efficiency.

● Countertop: T-shaped aluminum profile

● Control: Adopt genuine Xingxing multi-dimensional special system, list processing, program admission at one time, batch sequential processing, avoid manual selection, eliminate errors, and improve processing efficiency.

Performance Index

Model NO | HP-1325A Wood CNC Router |

Table Size | 1440×3000mm |

X Y Z Traveling Area | 1300x2500*200mm |

Table Structure | T-slot |

X Y Transmisson | Rack Gear |

Z transmission | Germany Neef Ball Screws |

X Y Z Guide Rail | TAIWAN HIWIN Square Rail |

Spindle Power | 3.0 kw Water Cooling Spindle |

Max Spindle Speed | 24000r/ min |

Max Traveling Speed | 35m/s |

Max Working Speed | 30m/s |

Processiong Accuracy | ±0.025mm |

Reposition Accuracy | ≤0.025mm |

Working Voltage | 220/380V 50Hz |

Work-holding | Clamps |

Processor | Windows /100MHz |

Interface | PCI |

Command | G*.u00*.mmg*.plt |

Operation System | Nc-studio |

Power(not include the spindle) | 500W |

Net weight /Gross Weight | 1000KGS /1100KGS |

Package Dimension | 3200*1840*1900mm |

Services

1. training

The trainee must have certain relevant education and knowledge. The supplier will train the customer in programming, operation, processing and daily maintenance. The trainee must be fixed and study hard.

The technical engineer of the supplier pays a return visit to the customer from time to time, and conducts technical exchanges with the customer in terms of machine operation and product processing. The user can consult our company any questions by phone and email at any time.

2. After-sales service

Free maintenance of the machine during the warranty period

The free warranty period is one year.

The whole process of processing and testing:

1. Steel plate integral airframe welded fuselage

2. Rough machining of gantry milling machine

3. Internal stress relief treatment:

1) Tempering (annealing) heat treatment of gantry beam and side arm

2) Aging treatment of bed vibration

4. Finishing:

1) The imported pentahedron machining center (mother machine) is used to locate and fix the body at one time;

2) The installation reference surface of the overall precision milling X, Y, Z three-axis bidirectional guide rails and racks;

3) After the datum surface processing is completed, under the same positioning accuracy, the one-time processing of the positioning pin holes, fixed installation holes and screw holes of the installation reference surface of the X, Y, and Z three-axis bidirectional guide rails is completed.

5. Transfer to the assembly process and assembly

6. Quality inspection process

1) Precision ruler and dial indicator: check the straightness of X, Y and Z axes

2) Precision ruler, dial indicator, spirit level, and laser interferometer detect the parallelism between X, Y, and Z guide rails

3) Precision angle ruler, dial indicator, special inspection tool, ball bar: detect the verticality of X, Y, 7. Three-axis guide rails

4) Dial indicator, special inspection tool: spindle verticality detection

5) Special inspection tool, dial indicator, precision angle ruler: detect the parallelism and perpendicularity of X, Y, Z rack and lead screw and the corresponding linear axis (guide rail)

7. paint, packaging

8. Factory

Related News

Submitted successfully

We will contact you as soon as possible